Industry news|2022-03-11| admin

Below are several common failure modes of gears.

1. Broken gear teeth

Under the action of the load, the bending stress generated at the root of the gear tooth is the largest, and there is a stress concentration. During the transmission process, the gear teeth are repeatedly loaded, and the bending stress of the tooth root is the alternating stress. Under the action of this alternating bending stress, fatigue cracks are generated at the tooth root, and the cracks expand, resulting in the bending fatigue fracture of the gear teeth.

When the gear is overloaded or subjected to impact load for a short time, or after the gear teeth are worn and thinned, the sudden breaking of the gear teeth is called overload breaking. Gears made of hardened steel or cast iron are prone to this form of tooth breakage.

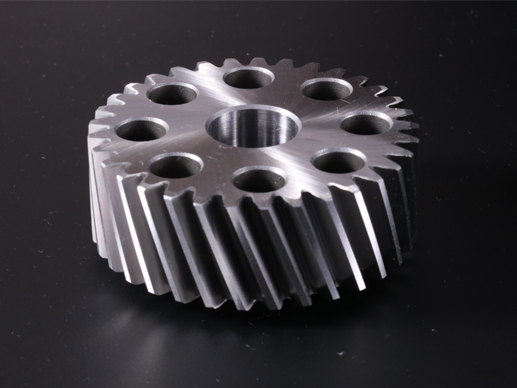

Spur gears are prone to full-tooth fracture, while helical gears are prone to partial inclination fracture of gear teeth due to the contact line being a diagonal line. Gear fracture is one of the most dangerous failure forms of gear transmission. It not only makes gear transmission completely ineffective, but also And the falling blocks often cause damage to other components, resulting in even greater failures.

Improve the performance of the material, increase the modulus appropriately, increase the excessive fillet of the tooth root, improve the manufacturing precision of the gear, reduce the roughness of the tooth root surface, eliminate the machining tool marks of the tooth root, and carry out shot peening and rolling strengthening on the tooth root. Treatment, etc., can improve the fracture resistance of the gear teeth.

2. Tooth surface pitting

When the gear teeth are loaded, contact stress occurs at the meshing point on the working surface. During operation, the contact stress of the tooth surface changes according to the pulsation cycle. Under the repeated action of contact stress, some tiny cracks will appear on the surface of the gear. After the crack area continues to grow, the material falls off from the tooth surface and forms pit-like pits, which is tooth surface pitting.

After pitting on the tooth surface, the tooth profile is damaged, which deteriorates the transmission performance and increases the vibration and noise. Pitting occurs mostly on the root surface near the pitch line. The reason is: when the gear teeth mesh near the pitch line, the number of tooth pairs meshing at the same time is small. For a spur gear, only one pair of teeth is in contact, and the contact stress of the tooth surface is large, and when the gear teeth are meshed near the pitch line, the tooth surface. The sliding speed is small and the direction of the speed changes, and the oil film is not easy to form between the tooth surfaces. Pitting corrosion may also appear on the top of the tooth when the installation is severely poor or the gear shaft is deformed greatly.